Are you looking to improve your insulation and add more protection to your home? Suntuf and Tuftex are two quality brands to improve your roofing panels. But which one is better?

Suntuf and Tuftex are both well-known roofing brands in the industry. Although they use similar names, there are more than a few differences between them.

Suppose you’re considering a roof replacement. Or even planning on installing a new one, let this post enlighten you. So now, let’s talk about these two and figure out what sets them apart!

Suntuf has excellent physical qualities and is a leading roofing material. Some of its applications include industrial roofing, cladding, and roof light. Meanwhile, for home additions, Tuftex panels are the best available ones. You can apply it in commercial and agricultural settings.

Both materials are lightweight and simple-to-setup and consist of Polycarbonate plastic. However, color options, fire rating, and temperature range differ. They also vary in size, application, and durability.

Suntuf Roofing Panels

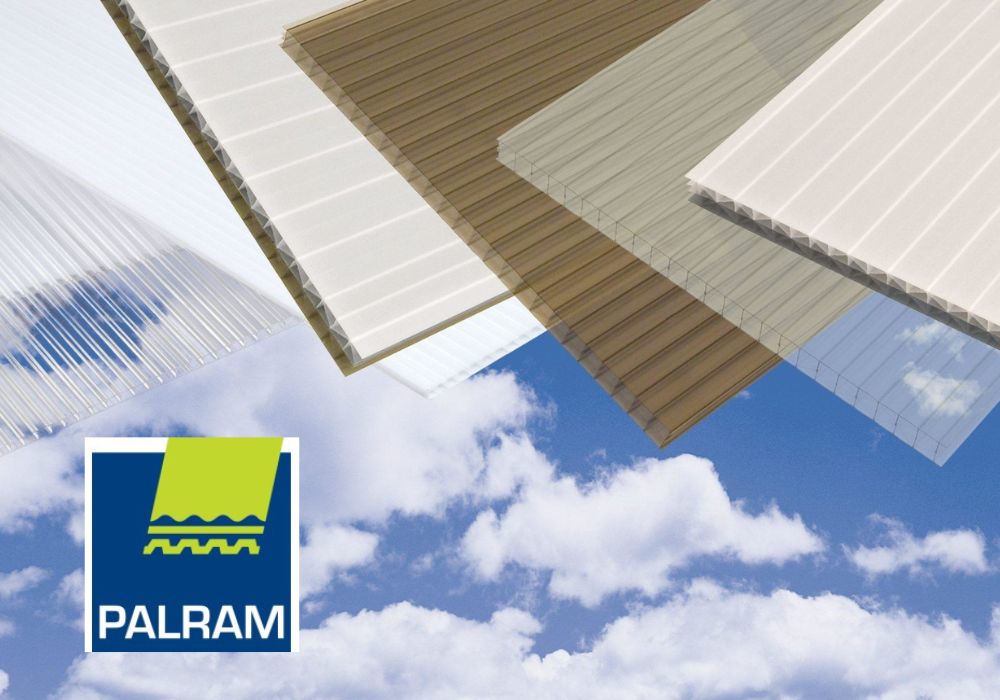

Palram manufactures Suntuf roofing panels. It is one of the world’s most prominent producers of thermoplastic sheets and panel systems. The company has come a long way since its establishment in 1963 by Kibbutz Ramat Yohanan in Israel.

Suntuf roofing panels are the best option because of their superior qualities. Since then, it has been widely installed all over the world.

Additionally, it has undergone extensive testing at reputable laboratories.

What Is Suntuf Roofing?

Suntuf is a material comprised of high-quality Polycarbonate plastic. The sheet is not only attractive, but it is also clear, lightweight, and durable.

As a polycarbonate material, it has many potential applications in the industrial sector. Thus Suntuf it’s highly adaptable and valuable.

Suntuf polycarbonate panels are long-lasting roof materials. In most cases, homeowners use it for everything from deck covers to skylights.

Some of its main benefits include:

- Very durable and resistant to damage.

- light-letting transparency of up to 90%

- Resistant from rain and sun

- Extensive temperature tolerance

- Reduces exposure to the sun by 99.9%

- Very light; weighs considerably less than a single glass.

- Excellent survival and fire ratings

- Simple in both design and installation

In addition to the standard clear, solar gray, Suntuf is also offered in a wide range of additional colors. These include opal white, red brick, misty green, hunter green, and smooth cream.

How Long Does Suntuf Roofing Last?

The durability of Suntuf roofing is 25 years. This is mainly on protection against light transmission. Additionally, it can last for 15 years against hail and breakage.

However, Polycarbonate, unlike acrylic, loses its color brilliance with time. Because of this, it then turns yellow when exposed to UV light.

Typically, environmental stress cracking occurs when PC absorbs chemicals. You can find these in hydrocarbons. As a result, it makes the material brittle and eventually leads it to break.

However, it can last long for 30 years or more. But it will depend on air pollution, winds, and installation practice.

Wipe your Suntuf roofing with a gentle sponge to keep it in excellent condition. Then add some warm, soapy water regularly.

Does Suntuf Reduce Heat?

Yes, Suntuf polycarbonate roofing can keep heat out. This makes it a great choice for sunrooms and patios with shade.

This material is stable even with prolonged exposure to -58° F temperatures. Thus, it can withstand intense temperatures of up to 184°F.

Like with any thermoplastic, polycarbonate expands when heated for the thermoforming process. It’s soft and elastic when exposed to sunlight. However, after cooling down, it re-sets its hardness.

As you can see, Suntuf Polycarbonate is not only versatile. But also incredibly durable, insulating against heat, cold, and UV radiation.

Overall, Suntuf roofing can cut heat transfer by around 55%. This can keep you warm without overheating, even on humid days.

How Strong Is Suntuf?

As mentioned earlier, Suntuf is a polycarbonate material. Compared to glass, Suntuf is 250 times stronger, while acrylic is 30 times stronger.

You can pair polycarbonate sheets with one solid wall or with multiple walls. They are clear, light, and very strong.

It has 9500 psi tensile strength. And another 9000 psi yields tensile resistance. Thus, this material can sustain extensive pressures. Therefore, it could survive a depth of almost 20,000 feet before deforming or breaking.

In terms of security, Suntuf material is nearly unbreakable. Contractors use it since it can withstand inclement weather. In most cases, they apply it to build hospitals and schools.

Tuftex Roofing Panels

Tuftex products are available from Onduline, North America. They offer goods in an application for homes, businesses, farms, and factories.

Onduline was first established in France in 1944 by Gaston Gromier. From then on, it has expanded its revolutionary roofing system offerings. Thus, it also positioned itself as the industry leader in the field.

Since then, they have produced thin roofing sheets of fibers and bitumen for pitched roofs.

How about we dive into the specifics?

What Is Tuftex Roofing?

Tuftex roofs consist of the octagonal-wave profile of polycarbonate thermoplastic polymer.

If you need a panel that lets some light through, you can use any of Tuftex’s products outside. Greenhouses and garden sheds can all benefit from using Tuftex roofing panels.

Their primary advantages include the following:

- It keeps its color and opacity

- Strength up to 20 times that of fiberglass

- Virtually 100% protection from dangerous UV rays

- It withstands a wide range of temperatures

- Wind and Hail Proof

- Not going to rust or corrode

- It can be set up with common equipment

- A Guarantee That Lasts Forever

In addition, there are eleven color options for Tuftex Roofing Panels. Each color contributes a distinct brightness to the overall effect.

What Are Tuftex Panels Used For?

Tuftex panels are the best building panels for residential, commercial, and agricultural applications.

You can apply it as deck covers, sun porches, carports, patio covers, and privacy panels. Remember not to use them as the principal roofing material in any construction.

Typical Applications

Residential: Patio covers, carports, greenhouses, sunporches, do-it-yourself projects. These are just a few residential uses for this versatile material.

Commercial: Warehouses, commercial greenhouses, restaurant patio enclosures. These commercial uses are just some places where Tuftex panels shine.

Agricultural: Tuftex’s high impact strength makes it the finest option for agricultural settings. These include interior walls and ceilings in agricultural animal enclosures. Specifically, you can use this in dairy farms and hog farms poultry farms. Also in kennels riding arenas and truck washes storage facilities factories.

How Long Does Tuftex Roofing Last?

The lifespan of Tuftex Roofing Panels is roughly 10-15 years.

They can even withstand being slammed into a wall. They can also resist exposure to strong sunlight because of how they are greatly constructed. Hence, unlike fiberglass, it won’t break down and flake.

In most cases, homeowners apply Tuftex to greenhouses. It has double-layered polycarbonate acrylic roofs with webs in between the layers. This durable roofing material can endure for up to a decade and is ideal for sloping roofs.

Keep in mind that a double-layer construction raises the possibility of moisture buildup. Also, it can contribute to the accumulation of algae if not fitted during installation.

How Strong Is Tuftex?

When compared to 5 oz. fiberglass corrugated panels, the strength of Tuftex panels is 20 times greater. They can resist surface temperatures between 270- and -40 degrees Fahrenheit.

Additionally, Tuftex Vinyl panels can withstand 150 deg F without affecting their durability. That is why this material is suitable for the surface temperature of a ceiling.

However, you should only use transparent vinyl panels in areas with moderate UV. Thus, be cautious in using it on surface temperatures below 125 F.

As you can see, Tuftex is resistant to the damaging effects of saline water and animal waste. Moreover, it can also resist acidic chemicals. Unlike fiberglass, its flat surface does not attract dust and debris. Therefore, cleaning is easier.

In addition to being fireproof, it won’t melt like fiberglass would.

What Is the Difference Between SUNTUF And Tuftex?

Both Suntuf and Tuftex consist of premium-grade Polycarbonate plastics. However, the range of colors and expected lifespan is not the same. They also differ in applications and their ability to withstand extreme temperatures.

Generally, Suntuf roofing has a 25-year lifespan. Its primary function is to block out sunlight. It is also resistant to fracture and hail for 15 years. Meanwhile, Tuftex roofing panels last for about 15–20 years.

Suntuf also comes in 16 color choices. Opal white, red brick, misty green, hunter green, and silky cream are some available colors. On the other hand, you can purchase Tuftex roofing panels in 11 distinct shades.

In addition, Suntuf maintains its stability at -58 degrees Fahrenheit for long periods. As a result, it can hold up to temperatures of 184 degrees Fahrenheit. Tuftex is durable enough to withstand temperatures from 270 to -40 degrees F.

Moreover, Suntuf is 250 times stronger than glass. At the same time, Tuftex panels are 20 times stronger than fiberglass corrugated panels.

Finally, Suntuf is ideal in residential settings like deck covers and greenhouses. In comparison, Tuftex panels are effective in commercial and agricultural applications.

Which Is Better, Polycarbonate Or Fiber Sheet Roofing?

Polycarbonate is the better option for roofing compared to fiber sheet materials.

Fiberglass, in contrast to polycarbonate, melts under high temperatures. Hence, the fibers weaken from exposure, leading to yellowing or staining. Therefore, polycarbonate sheets are superior due to their strength, longevity, and adaptability.

Additionally, polycarbonate sheets have 4 times the impact resistance of fiberglass enclosures. It can survive impacts of over 900 pounds.

In most cases, the appearance of a polycarbonate sheet is attractive. It has a sleek design, is incredibly lightweight, and lasts long. Most importantly, you can purchase it in a transparent sheet.

In other words, you can avoid the expense of installing electrical fixtures by making 25% of your roof see-through. This will allow natural light to lighten the space and make it more sanitary.

Which Is Better, PVC Or Polycarbonate Roofing?

In comparison to PVC, polycarbonate performs far better. It has an outstanding impact strength for thermoplastic. Thus, it is widely known as a tough roofing material.

Polycarbonate is more durable than PVC, so it typically has a longer warranty. This is because polycarbonate is the same material used to produce bulletproof glass.

In contrast to polycarbonate sheets, PVC roofing sheets are not easily scratched. PVC sheets have excellent transparency. This allows plenty of light to enter the space via the roof.

However, remember that PVC roofing sheets will save you money over polycarbonate.